How the NY SMART I-Corridor will Advance Global Semiconductor Innovation, Manufacturing and Workforce Training

Posted On |

Image

|

The NY SMART I-Corridor Tech Hub spans the Buffalo, Rochester, Syracuse and Ithaca region and was developed by a consortium of partners that has engaged 100+ institutions, including assembling commitments from industry, academia, labor, nonprofit, government and other private sector members. The implementation phase of the program will allow the region to expand the semiconductor ecosystem already in existence to develop and make the future of semiconductor technology in Upstate NY.

By the end of the decade, 25% of all chips produced in the United States will be manufactured within 350 miles of this Tech Hub – with no other region in the nation accounting for a greater share of microchip production. The $40 million in Tech Hubs investment will fund specific component projects that aim to solve the growth challenges the region would otherwise face over the coming decade, and ensure that growth is translated to all members of the communities.

The funding will focus on key areas across all regions including:

Workforce Training:

Led by Monroe Community College, the workforce training program will create a variety of initiatives, including expanding internship and apprenticeship opportunities; establishing a program to pair industry partners with semiconductor supply chain firms to develop training and job placement efforts; and creating employer-led training initiatives at regional training and education institutions to expand the workforce. Fabs and suppliers in the corridor will face a gap of over 10,000 jobs by 2034, which requires immediate action to train workers for 5,000 middle-skill jobs like electrical assemblers and processing technicians, 4,000 construction jobs like electricians and welders, and 2,500 high-skill engineering jobs like industrial engineers and software developers.

This initiative, called STEP UP (Semiconductor Talent & Employer Partnership in Upstate New York) will focus on closing these critical gaps in upskilling, hiring and retention, especially for populations that have been historically excluded from tech and manufacturing related job opportunities. Partners will also work through New York State’s ON-RAMP program alongside, community-based organizations , and training providers to recruit from historically underserved communities and provide wraparound services. STEP UP will also develop new curricula or certification programs that workers will need to be placed into semiconductor jobs. For example, MCC plans to add new curriculum and credentialing programs to its existing Optical Systems Technology Program. MCC is the nation’s only community college awarding associate degrees in precision optics. Many of these graduates today are employed at I-Corridor chip supply chain manufacturers like Corning and Optimax, however fabs will also need specialized types of optical technicians since chip manufacturing involves many optical/photonic processes like lithography. MCC can leverage its optical program and the state-of-art equipment in the MCC FWD (“Forward”) Center in downtown Rochester to work with industry to design new curriculums that can be used by MCC and other training providers in the Tech Hub Corridor to train workers in Buffalo, Rochester and Syracuse.

Supply Chain:

Led by University at Buffalo, this component would aim to close gaps in the supply chain by making it easier for local firms to gain access to growth opportunities in the semiconductor industry. Federal funds will be allocated to scale capacity at three regional Manufacturing Extension Partnerships; increase visibility of new opportunities; track regional growth opportunities; and assist firms with access to capital for the growing semiconductor industry. This would help leverage the 100+ existing semiconductor suppliers around in the region to help them expand their capabilities and help other legacy manufacturers upscale to enter into the semiconductor supply chain. This will help link the already robust manufacturing environment with supply chain opportunities associated with the presence of new major semiconductor companies like Micron coming to the region. This initiative will help guide manufacturers through assessments to understand how their products fit into the broader semiconductor supply chain and develop pathways to obtain the right certifications and other expertise necessary to make them eligible to sell into these fabs.

Commercialization:

Led by Syracuse University, this project will coordinate the Tech Hub’s key commercialization assets and facilities across academia, government and industry to help startup, small- to mid-size, and minority-owned businesses access critical resources for semiconductor-related innovation and entrepreneurship, to help them bring their ideas to market more successfully. These businesses commonly face significant barriers to successful commercialization, including the scarcity and expense of state-of-the-art equipment and facilities, limited capital availability for research, development and prototyping, lack of participation from underserved and underrepresented populations, and more.

This project also aims to increase access to critical commercialization resources by creating a centralized inventory of I-Corridor commercialization assets and facilities that businesses can view and book through an online public portal. An “innovation concierge” will help businesses navigate the portal and drive awareness of entrepreneurial support in underrepresented communities. In addition, the project will finance semiconductor-related research experiences like internships and co-ops for underrepresented students, and standardize inter-institutional IP-sharing to help collaborators identify, mitigate and avoid the bottlenecks that commonly delay R&D, frustrate business development and disincentivize investment.

The Tech Hub has assembled many of the country’s leading semiconductor-related commercialization resources as partners for the project, including INFICON’s state-of-the-art tools and cleanrooms, SUNY ESF and Clarkson University’s Healthy Water Solutions, Cornell’s NanoScale Facility, the University of Rochester’s URNano, NY CREATES Albany Nanotech Complex, AIM Photonics Test Assembly and Packaging facility, Luminate’s Optics, Photonics, and Imaging Startup Accelerator, NYSTAR’s Centers for Advanced Technology and Centers of Excellence, and more.

The application was led by three designated conveners, one from each region: CenterState CEO in Syracuse, Buffalo Niagara Partnership in Buffalo, and ROC2025 in Rochester.

Other

CEO News

CEO News | 02/06/2026New Benefit Gives Members Access to Speakers Through TalkadotCenterState CEO is excited to introduce a new member benefit through a partnership with Talkadot (www.talkadot.com), a data-driven speaker booking platform. CenterState CEO members now have unique access to Talkadot, providing a… |

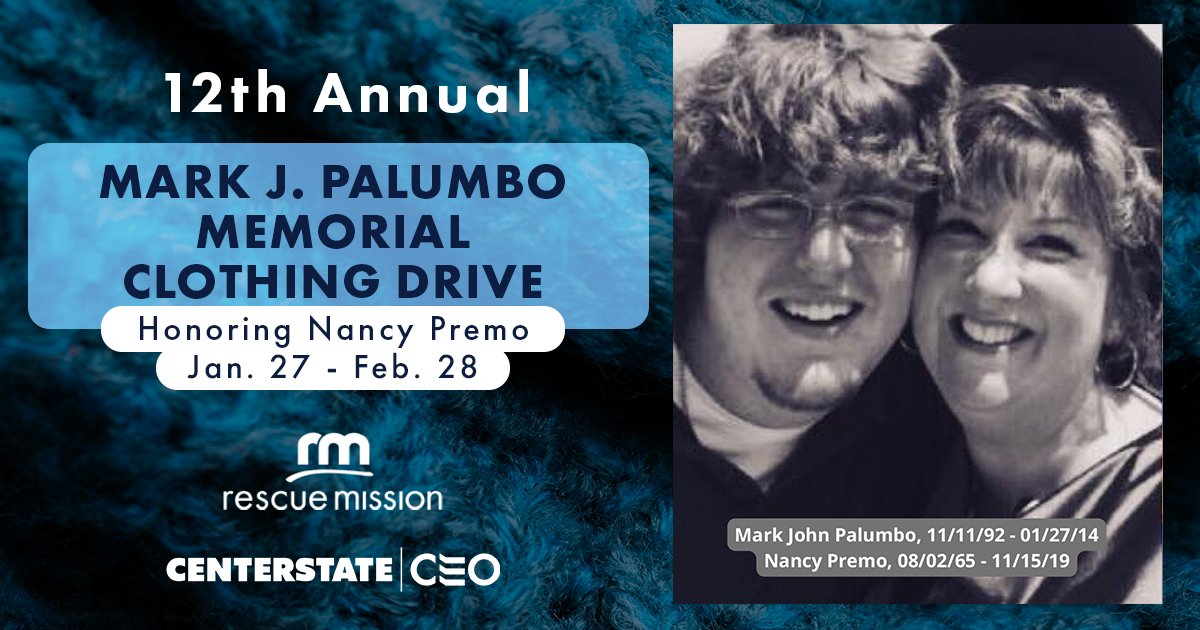

CEO News | 01/16/202612th Annual Mark J. Palumbo Memorial Clothing Drive, honoring Nancy PremoCenterState CEO is hosting the 12th annual Mark J. Palumbo Memorial Clothing Drive in honor of Nancy Premo. Bring gently used items such as winter coats, hats, sweatshirts, gloves, scarves, sweaters and warm socks to CenterState CEO's… |